The history of currently popular ink-jet printing, or, scientifically speaking the technology of nonimpact high-speed ink spotting through microscopic openings onto the solid carrier for producing an image on the surface of it, is more than a decade long. But the origin of this technology is actually the research of the Frenchman Felix Savart, who in 1833 have discovered and noted the uniformity of liquid drops formation when delivered through a narrow opening. It was first described mathematically in 1878 by lord Reilly (the future Nobel Prize Winner). However, many years on, in 1951, Siemens patented the first device that was separating the jet into similar drops. This invention led to the creation of minograph, one of the first commercial recorders used for the registration of voltage magnitude.

In the early 1960th, professor Suit from Standford university have shown that by applying pressure waves the liquid flow could be split in drops of the same size and distance to each other. Continuous flow of drops could be selectively charged. When passing through the electrical field, charged drops were deflected and stored in the recycling collector, while not charged ones were flying by the collector and reaching the solid carrier producing the given image. This process was called “continuous ink jet printing”. In the late 60th the invention of Mr. Suit led to devices like A. B. Dick VideoJet and Mead DIJIT.

In the next decade the well-known IBM Company have licensed the described above technology and launched an extensive program of adaptation of the technology in their own printers. The first result that came up was the IBM 4640 printer, which was presented in 1976 as a “hard carrier peripheral text printing device”.

Approximately at the same time, Professor Hertz from the Lund University, Sweden, independently developed a number of continuous ink jet printing methods, with the possibility of adjusting the parameters of the drop flow in grayscale printing. Among his developments there was a method of controlling the amount of drops per pixel, that allowed you to adjust the ink density and get required gradations. This method was later licensed by a number of companies including Iris Graphics and Stork, for the commercial production of qualitative images on the market.

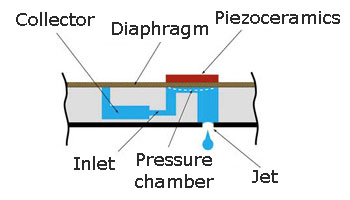

Despite of such an active continuous ink jet printing development, you should remember about drop-on-demand method, the main point of which was for the device to release drops only when they needed to reach the carrier. Obviously, this method eliminated both the complex system of charging/deflecting drops and insecure recirculation systems. Groundwork from this area was implemented in Siemens PT-80 sequential character printing device in 1977, and also in Silonics printer that arrived a year later. Electrical impulses in these devices were driving ink drops out due to the pressure wave, created by the mechanical movement of the piezoceramic element.

In the following years, including 1980th, the drop-on-demand technology was developing, evolving and giving birth to the new commercially manufactured printers. It was assumed that the simplicity of ink application blocks will make ink-jet printers highly reliable. Nevertheless, the issues were all the same, and what made it even more undesirable is the typical plugging of jets and inconsistency of the image quality.

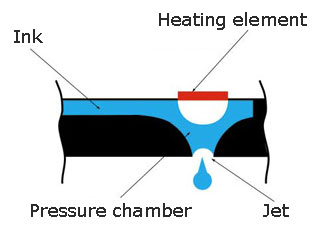

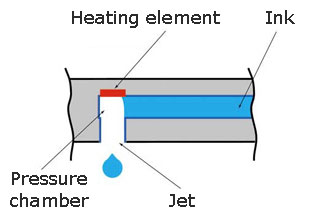

In 1979 Canon came up with a printing method that was based on the drop-on-demand technology, according to which the drops were ejected from jets due to the growing and collapsing fog-like ink particles on the surface of a small heater located next to the jet. Canon called the technology “bubble jet”. The simplicity of such a printhead and the ink application accuracy that was achieved by the existing manufacturing technologies, have made this solution quite cheap having the high-density jets.

Approximately at the same time, Hewlett-Packard have independently developed a similar technology called “thermal inkjet”. And in 1984 it released a solution called ThinkJet – the first commercially successful and relatively cheap ink-jet printer that was based on the bubble jet technology.

The price of a 12 jet ThinkJet printhead was sufficiently low, so you could be able to just throw it out after the cartridge was used. Having made a replaceable printhead the company solved an eternal reliability challenge. Since that time, the technology has been constantly developed by Hewlett-Packard and Canon, whose efforts were rewarded by the success. It is clear that this success was achieved by the constant upscaling of the print resolution and the color range extension followed by the reduction of prices. Starting from late 1980th, due to the low cost, compact sizes, quiet performance and, of course, the color range, the ink-jet printers with thermal inkjet or bubble jet technologies were becoming more and more viable alternative to matrix printers among the end users, and after all conquered the market of cheap color printing devices.

Adapted from http://www.ixbt.com/