There’s a mark or an arrow imprinted on the most feed tires with the textured surface, so called “crepe-style” feed tires. It is very important to install them properly, so the imprinted sign (mark or arrow) will point the proper direction of the tire rotation. In certain cases the “proper direction” means that the side where the arrow is, need to face the user; and in the other the arrow should face the rear of the devise you’re printing with. Continue reading Install your Feed Tires properly to get the best performance

There’s a mark or an arrow imprinted on the most feed tires with the textured surface, so called “crepe-style” feed tires. It is very important to install them properly, so the imprinted sign (mark or arrow) will point the proper direction of the tire rotation. In certain cases the “proper direction” means that the side where the arrow is, need to face the user; and in the other the arrow should face the rear of the devise you’re printing with. Continue reading Install your Feed Tires properly to get the best performance

Monthly Archives: November 2014

Printing technologies – matrix printing

Matrix printing is the most respectable, according to the age, process, that still enjoys its popularity. The technology is simple: to receive an image, dots are applied to the paper. These dots are made by the printing head needles when they hit the paper through the ink ribbon. Needles are gathered in vertical rows. There are two types of printers according to the number of needles: 9 needle printers (where the printing head has one row with 9 needles) and 24 needle printers (where the printing head has two rows with 12 needles in each one). There are printers with 18 needles in printing head. Such heads are used in high-speed printers. In these heads, needles are arranged rhombic. Such an arrangement provides high-speed printing with the equal force of impact on the central and the outer needles. The printing quality of this printer fully complies with the printing quality of 9 needle printer. The “excess” of the needles is used for increasing the speed, but not the quality (it is known, that the printing quality of the 24 needle printer is noticeably higher than the quality of 9 needle one). Continue reading Printing technologies – matrix printing

Matrix printing is the most respectable, according to the age, process, that still enjoys its popularity. The technology is simple: to receive an image, dots are applied to the paper. These dots are made by the printing head needles when they hit the paper through the ink ribbon. Needles are gathered in vertical rows. There are two types of printers according to the number of needles: 9 needle printers (where the printing head has one row with 9 needles) and 24 needle printers (where the printing head has two rows with 12 needles in each one). There are printers with 18 needles in printing head. Such heads are used in high-speed printers. In these heads, needles are arranged rhombic. Such an arrangement provides high-speed printing with the equal force of impact on the central and the outer needles. The printing quality of this printer fully complies with the printing quality of 9 needle printer. The “excess” of the needles is used for increasing the speed, but not the quality (it is known, that the printing quality of the 24 needle printer is noticeably higher than the quality of 9 needle one). Continue reading Printing technologies – matrix printing

Cartridge malfunction

Usually, cartridge malfunctions because of the main cartridge components. They are: OPC drum, doctor blade, magnetic roller, wiper, charging roller. Other malfunctions may be caused by the bad quality contacts, rivets, shutters, bushings or the body of the cartridge. These are general problems, they do not relate to certain cartridge models. If you want to know about possible malfunctions with certain cartridge, you should better look up the instruction for each particular cartridge. Continue reading Cartridge malfunction

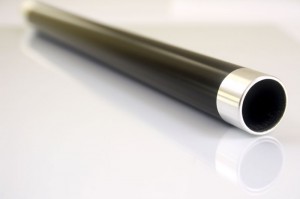

Once again on heating rollers

In printers or copiers teflon (heating) roller plays a decisive role in the quality of printed images. And while some users may not know what is teflon roller and what are its functions, they notice when it is not operable.

The main function of teflon roller is continuous fusing process, fixing of toner on paper or fabric. The task seems simple, but it requires qualitative performance, with accurately applied balance, set temperature and for a definite period of time. With the right combination of these factors image is impossible to print without defect. However, a small error in one of two variables can result in blurred images, streaks, double prints or can cause paper jam. In many cases, the cause of the defects is faulty heating roller and it often appears the last checked during the diagnosis of the device unit. Continue reading Once again on heating rollers

The main function of teflon roller is continuous fusing process, fixing of toner on paper or fabric. The task seems simple, but it requires qualitative performance, with accurately applied balance, set temperature and for a definite period of time. With the right combination of these factors image is impossible to print without defect. However, a small error in one of two variables can result in blurred images, streaks, double prints or can cause paper jam. In many cases, the cause of the defects is faulty heating roller and it often appears the last checked during the diagnosis of the device unit. Continue reading Once again on heating rollers